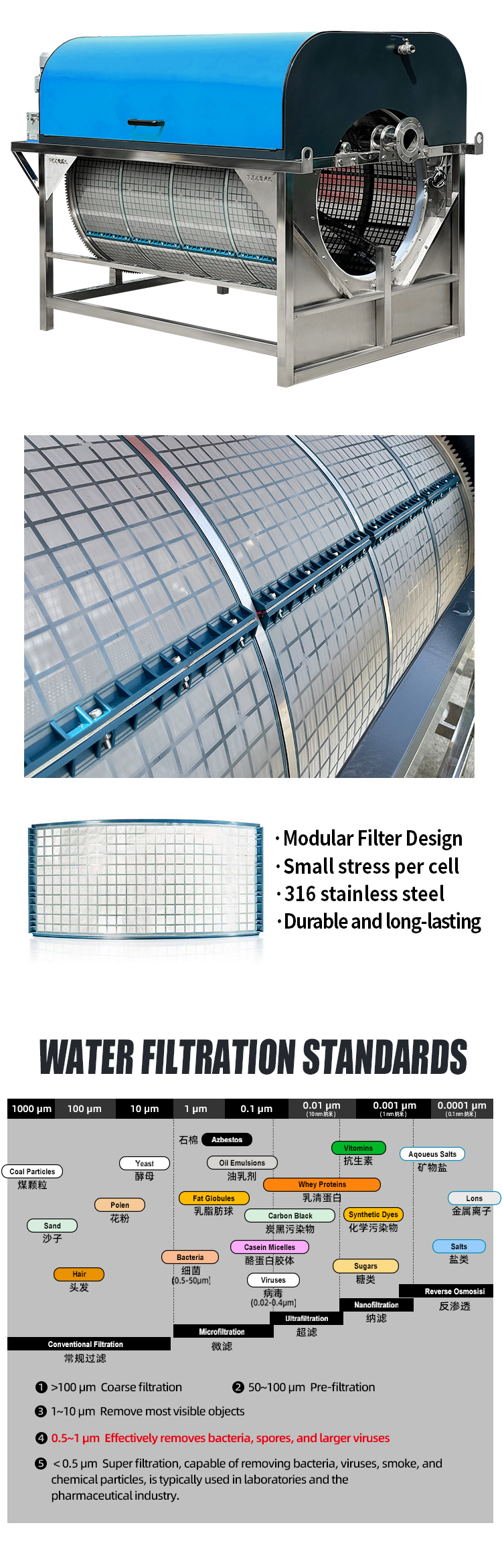

Custom Submerged Drum Filter for High-TSS Applications

When your system’s dealing with high solids loads, standard filters choke. Literally.

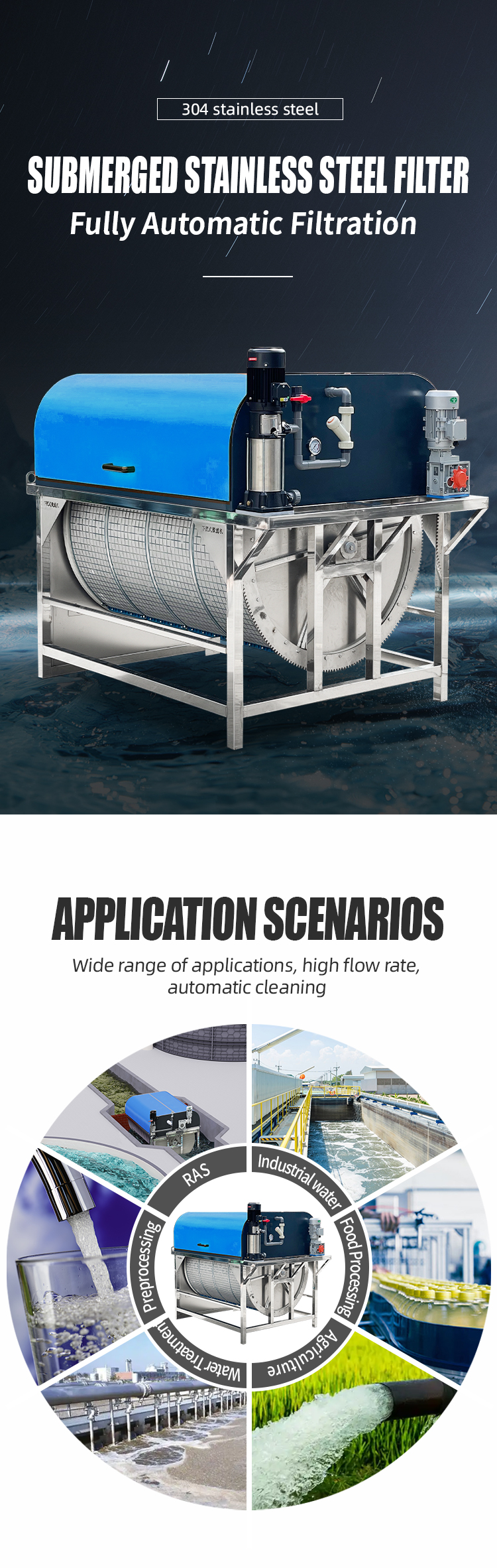

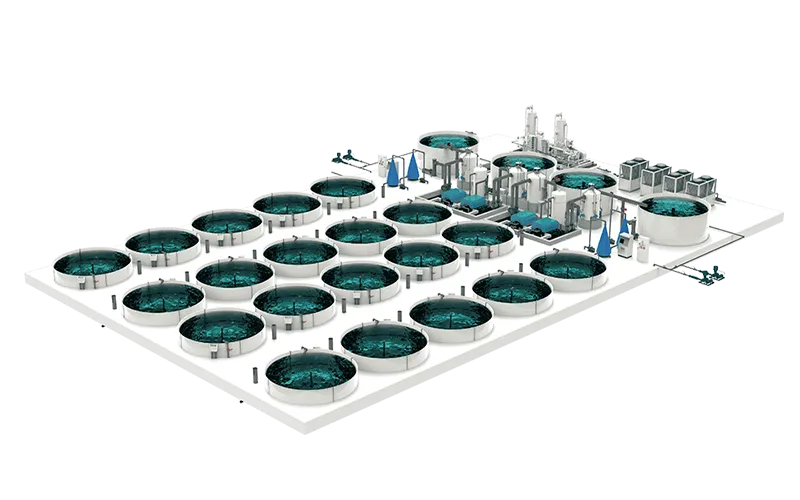

This Custom Submerged Drum Filter from YUTANK isn’t some off-the-shelf “maybe-it’ll-fit” setup. It’s made for serious TSS (Total Suspended Solids) removal in RAS systems, nurseries, or retrofits where flow rate, water depth, and footprint constraints are non-negotiable.

Instead of forcing water through pipe loops and wasting energy on unnecessary lifts, this unit drops directly into your sump or tank, working with the system’s natural water level. The result? No extra head loss, no complicated plumbing, and far fewer maintenance headaches.

The drum itself? Fully submerged, corrosion-resistant, and equipped with precision 60–74μm wedge wire screens that trap suspended solids before they reach your biofilters or UV.

Every spec is dialed in for your project—drum size, immersion depth, inlet/outlet position, filter mesh type, even motor brand if needed. It’s the kind of unit that fits right the first time, no on-site hacks required.

If your RAS flow is pushing serious volume or your waste load’s above average, this is the filter you bring in to clean things up.

Share:

Accessories:

Most filtration systems need your facility to adapt to them. This one adapts to you.

The YUTANK Custom Submerged Drum Filter is built for aquaculture professionals who don’t have the luxury of redesigning their entire water flow layout just to add a filter. Whether you’re running a high-load sump, a gravity-fed raceway, or a retrofit upgrade, this unit is all about plug-and-perform—with no need for lifting pumps, elevated skids, or re-routed piping.

Let’s break down what makes it tick:

💧 Built for High-Solids Workloads

The filter drum uses 60μm or 74μm stainless steel mesh, wrapped in a corrosion-resistant structure that lives fully submerged. Incoming water enters via gravity—no need for pressurized intake—and solids are trapped on the inside of the rotating drum. A backwash system mounted above the water line sprays the drum exterior, pushing waste into a collection trough.

Translation? You’re getting continuous microfiltration, even under heavy bio-loads, without clogging or gunk buildup.

🛠 Customization That Actually Matters

You can define the:

-

Drum diameter and length based on your flow rate (from pilot scale to >100 m³/h)

-

Submersion depth to match sump design

-

Mesh size based on species, feed, and solids type

-

Flange and outlet port positions to match your layout

-

Drive motor specs (torque, IP rating) depending on humidity or salt exposure

If you’re working with non-standard tank geometries or space-constrained areas (like retrofitted concrete basins), this flexibility saves you days—sometimes weeks—of trial and error.

🔩 Designed for Simplicity

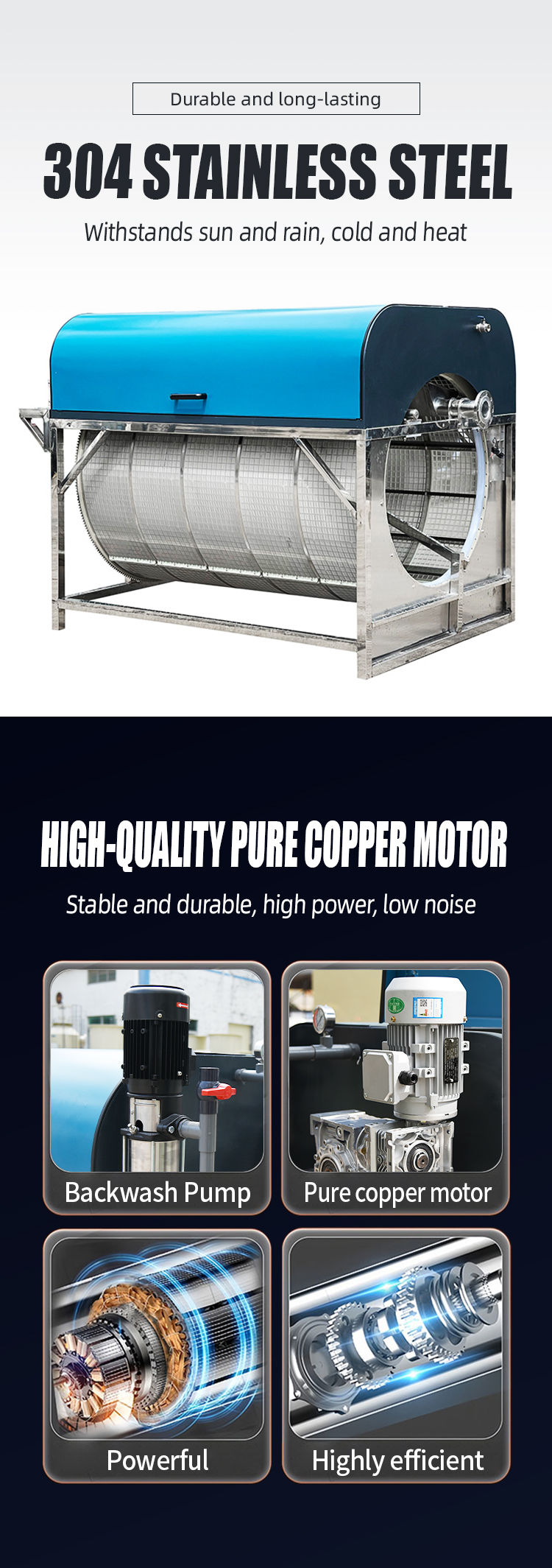

Every Submerged Drum Filter from YUTANK is built with:

-

304 or 316 stainless steel structure

-

Quick-lift handles and anchor points

-

Pre-wired motor and control line

-

Backwash trigger by timer or water level

No overengineering. Just smart, sturdy construction with low-friction bearings, replaceable wear parts, and easy visual inspection access.

🌊 Seamless Integration in RAS Systems

It fits in clean—upstream of your biofilters, ozone reactors, or UV disinfection. And because it runs submerged, it takes zero additional footprint above your sump.

Your flow path stays smooth. Your solids stay out of the system. Your labor costs stay low.

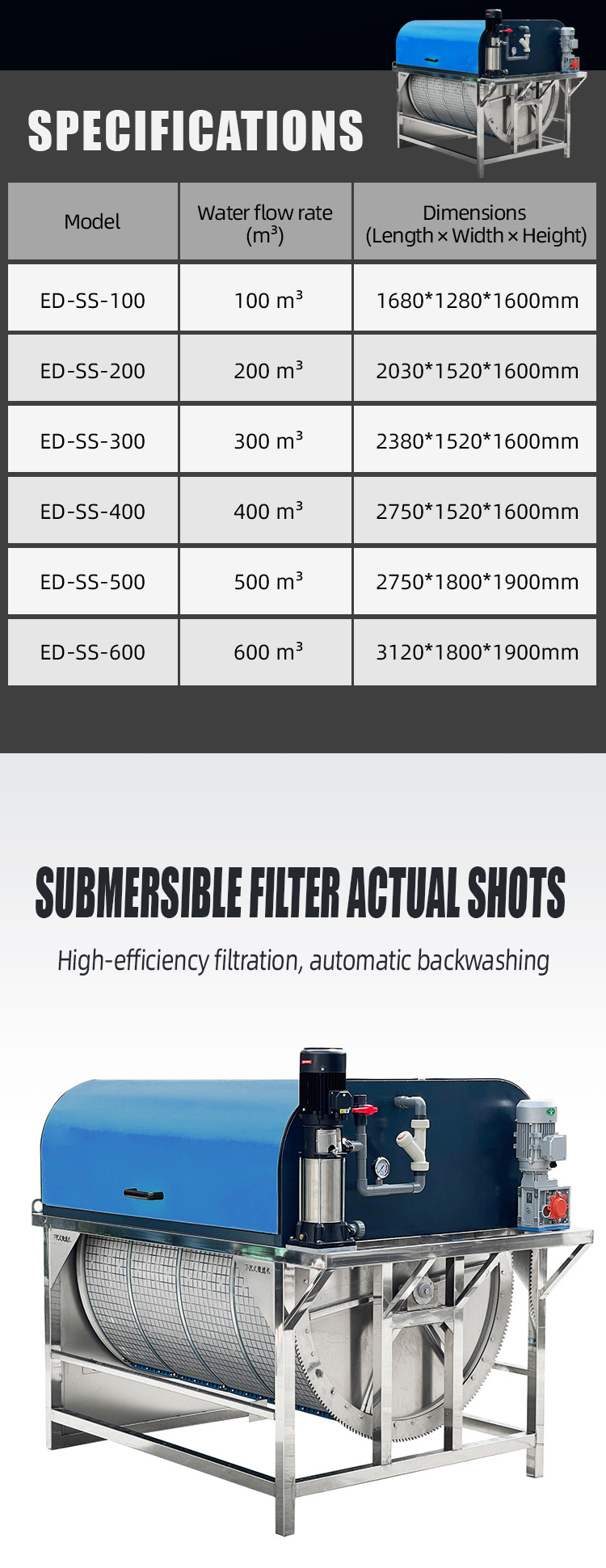

Below is a typical spec profile for a custom-engineered Submerged Drum Filter built for high-TSS loads. Remember: every dimension, flange, or mesh size can be tailored based on your RAS layout, fish species, and filtration goals.

These specs are adapted from verified YUTANK builds deployed in live systems

| Parameter | Typical Range / Options |

|---|---|

| Filtration Capacity | 10 – 100+ m³/h (custom per flow rate) |

| Mesh Opening Size | 60μm / 74μm wedge wire screen |

| Drum Material | 304 or 316L stainless steel |

| Frame/Housing Material | 304 stainless steel (submersible rated) |

| Drive Motor | Branded, IP55+ waterproof motor |

| Backwash Type | Automatic spray pump (level/timer triggered) |

| Submersion Depth | Custom to match tank/sump waterline |

| Inlet/Outlet Ports | Customizable flange positions (DN110–DN160 std) |

| Waste Discharge Outlet | Top-mounted trough + gravity flow exit |

| Installation Mode | Drop-in (sump/channel), no elevation needed |

| Power Supply | 220V / 380V, 50Hz or 60Hz compatible |

| Cleaning Access | Quick-lift handles + removable drum access |

| Control Interface | Manual switch / optional PLC-activated |

If you’re operating at the edge of your current filtration capacity or scaling up solids load, we can calculate the exact throughput based on your stocking density and retention time requirements.

Want the CAD layout or pressure loss estimate? That’s included once we scope your system layout.

Custom Submerged Drum Filter for High-TSS Applications

Product FAQs: Custom Submerged Drum Filter for High-TSS Applications

Q1: What is a Submerged Drum Filter and how does it work?

A1: A submerged drum filter is a filtration device that operates while partially submerged in the water body. It is typically installed directly within a sump tank or filtration channel. Its working principle relies on gravity (water level difference) from the aquaculture water to drive the flow through the drum. Solid impurities (TSS) in the water are trapped on the inner surface of the drum’s mesh screen. When impurities accumulate to a certain level, the system automatically triggers a backwash, using nozzles to flush the debris into a collection trough for discharge.

Q2: Why is this filter suitable for “High-TSS (Total Suspended Solids)” applications?

A2: A high-TSS environment means the equipment must handle more solid waste and endure greater wear. Our custom design addresses this challenge in the following ways:

- Robust Materials: The main body uses a stainless steel frame and drum for excellent corrosion resistance. For high-wear applications, we can upgrade key components (like the filter mesh and bearings) to 316 stainless steel.

- Reinforced Drive System: We offer optional brand-name motors with reinforced, widened gears and custom waterproof enclosures to ensure stable transmission even in humid, high-load environments.

- Efficient Backwashing: The system supports automatic, high-pressure backwashing linked to level sensors. When high TSS clogs the mesh and increases the water level differential, the high-pressure nozzles activate immediately to clean the screen, ensuring filtration flow is maintained.

Q3: What does “Custom” mean? What parameters can I customize?

A3: Yes, we offer comprehensive customization services. You can customize:

- Filter Precision: The standard mesh pore size is 60-74µm (microns), but this can be adjusted based on your aquaculture species or specific TSS particle size.

- Material Grade: You can select a 304 stainless steel body and upgrade key components to 316 stainless steel to suit seawater or highly corrosive environments.

- Size and Flow Rate: Our engineers will provide one-on-one design services using CAD and 3D modeling based on your existing channels, tank dimensions, or desired processing flow rate.

- Interface Standards: We can pre-fabricate flanges and openings to match European, American, or common Asian pipe standards.

- Electrical Specifications: We support global voltage and frequency adaptation (e.g., 110V/220V/380V; 50Hz/60Hz).

Q4: What are the advantages of a Submerged design compared to a Box-Type filter?

A4: The main advantages of the submerged design lie in its installation flexibility and hydraulic efficiency:

- Simplified Piping: It can be installed directly in a sump or channel, eliminating the need for complex inlet/outlet piping and additional pump head requirements.

- Energy Savings: It is ideal for low-head or gravity-fed systems.

- Space Savings: The installation is flexible and does not occupy extra floor space.

- Easy Retrofitting: It is particularly suitable for upgrading filtration systems in existing ponds or areas with limited space.

Q5: Is this filter difficult to install and maintain?

A5: We provide comprehensive support to simplify installation and maintenance:

- Installation Support: We provide detailed installation manuals and videos. For large-scale projects, we can dispatch engineers for on-site commissioning guidance.

- Ease of Maintenance: The open-frame design (similar to our KK series) allows for direct observation of the drum’s operation and mesh contamination. Components like the filter mesh, seals, and transmission parts are all designed to be quickly replaceable on-site.

- Important Note: The key to a submerged installation is the precise control of the immersion depth and water level, which is essential for optimal filtration performance.

Q6: How does YUTANK guarantee the quality of this custom filter?

A6: We ensure quality through a strict quality control process:

- Certification: We are ISO 9001 certified for quality management.

- Pre-Production Approval: For custom projects, we provide CAD drawings or 3D models for client approval before mass production.

- Final Inspection: Every unit undergoes a final functional and safety inspection before shipment.

- After-Sales Warranty: Core components (like motors and controllers) come with a 1-year warranty, and we provide lifetime remote technical support.

Q7: How can I get a custom proposal and quotation?

A7: Simply contact our sales team and provide as much of the following information as possible:

- Your water treatment goal (e.g., aquaculture species, main source of TSS).

- The total water volume or your desired processing flow rate ($m^3/h$).

- Details of the installation site (e.g., channel dimensions, tank depth, indoor/outdoor).

- Water type (e.g., freshwater, seawater, high salinity).Our engineers will then provide you with a one-on-one consultation and a detailed equipment configuration plan.

Download the User Manual

Get the complete user operation guide for YUTANK recirculating aquaculture system equipment, understand the product functions, specification parameters, installation steps, usage methods and solutions to common problems of the recirculating aquaculture system equipment, and help you quickly get started and use this product efficiently.

| Brochures and Overviews | Language | File Type | File Size | Download |

|---|---|---|---|---|

| Product Information - R1000 Distance Sensor | en | 1 MB | ||

| Product Overview - Photoelectric Sensors | en | 5 MB | ||

| Product Overview - Industrial Sensors, Systems and Communication | en | 3 MB | ||

| Product Information - R10x and R20x Series Standard Housings - All Sensing Modes | en | 3 MB | ||

| Product Information - M18 Series - Cylindrical Photoelectric Sensors | en | 389 KB | ||

| Product Information - Sensors and Systems with IO-Link | en | 5 MB | ||

| Product Overview - LiDAR Sensors | en | 2 MB | ||

| Product Information - Quick Select Product Guide - Industrial Sensors | en | 47 MB |