Protein Skimmer: Solutions for Dissolved Solids Separation

- Yutank@admin

Table of Contents

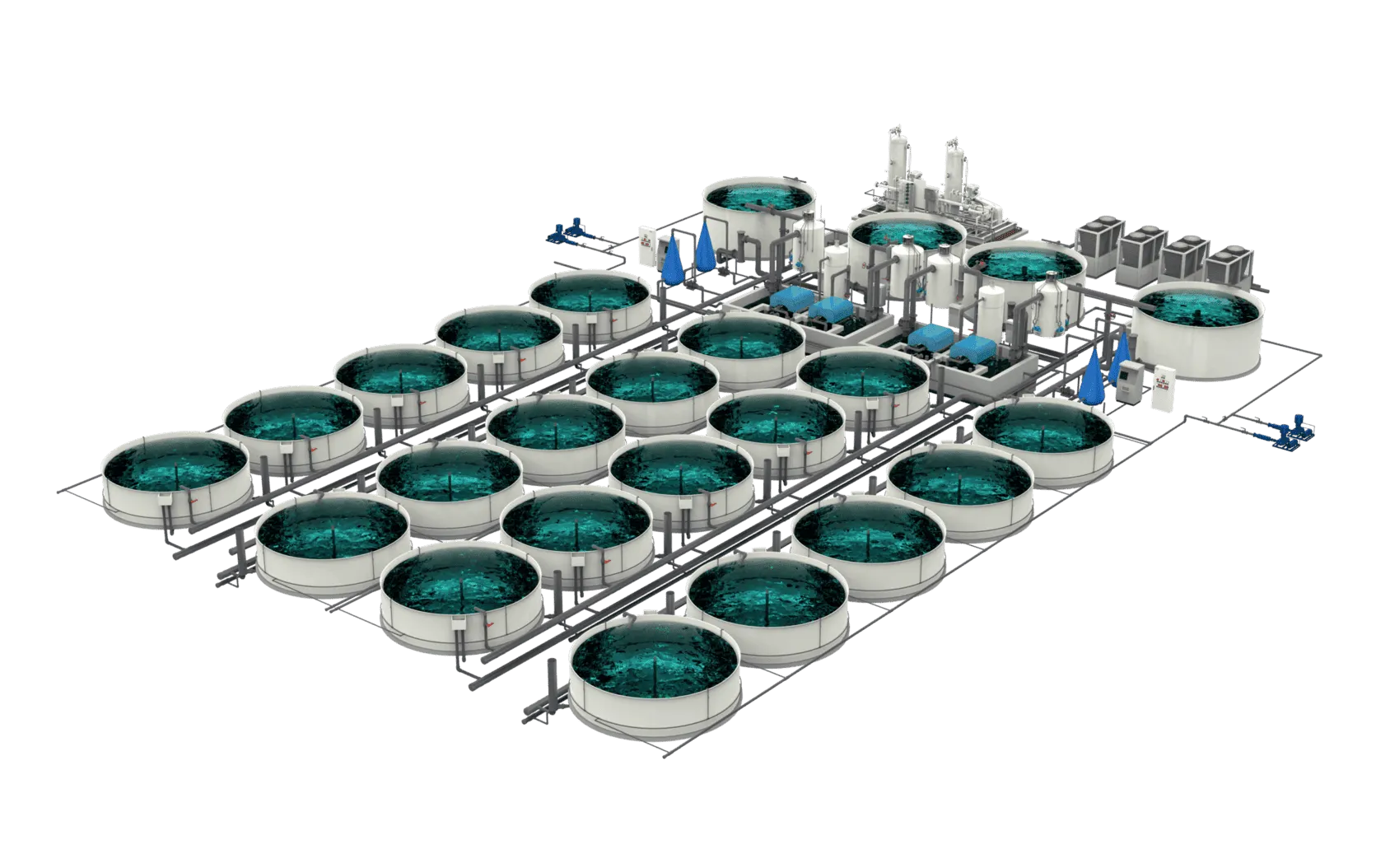

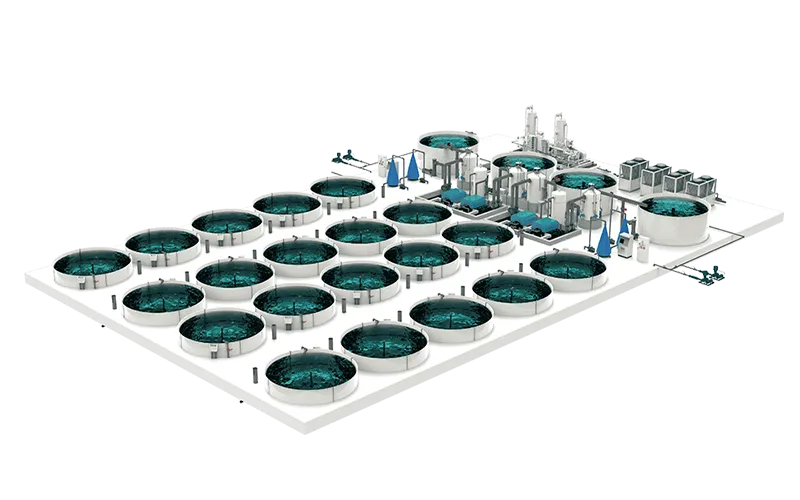

When your RAS water turns murky, the Protein Skimmer steps in—like a tiny bouncer tossing out microscopic troublemakers.

Protein Skimmer: Solutions for Dissolved Solids Separation

You ever walk into a room and instantly know something’s off? That’s what it’s like for fish in a recirculating aquaculture system when dissolved gunk—proteins, oils, fine particulates—starts piling up. Enter the Protein Skimmer: part magician, part janitor. It pulls out the microscopic muck before it turns your pristine tank into a swampy mess.

RAS techs often joke that water clarity is like trust—once it’s gone, everything else falls apart. Mechanical filters catch the big stuff, sure—but what about all that invisible waste floating just under the radar? That’s where this slick machine goes to work. It’s not magic foam—it just looks like it.

“With proper counter-current design and airflow calibration, skimmers can remove up to 85% of dissolved organics,” says Wei Liang, senior systems engineer at YUTANK (2024 product report). “It’s not just cleaner water—it’s healthier animals and lower mortality rates.”

Stick around—we’re gonna break down why this underrated tool might be your best insurance policy against cloudy chaos in your tanks.

Key Points For Protein Skimmer Performance In Aquaculture Systems

- Foam Fractionation Advantage: Protein skimmers use foam fractionation to extract fine particulates and dissolved organics that mechanical filters miss, ensuring pristine water conditions.

- Organic Waste Reduction: By removing up to 85% of dissolved organic waste through counter-current design, skimmers improve fish health and reduce mortality in RAS setups.

- Water Chemistry Balance: Skimmers contribute to stable pH levels and improved Redox potential, creating an optimal aquatic environment for species like shrimp or salmonids.

- Complementary Role With Filters: While mechanical filters trap large debris, protein skimmers target invisible contaminants—together they offer comprehensive water purification in closed-loop systems.

- Airflow Optimization Matters: Consistent foam production relies on proper airflow rate calibration and Venturi injector design, key for continuous performance in integrated aquaculture environments.

Three Reasons To Integrate Skimmer In Ras

Adding a skimming solution in RAS setups isn’t just smart—it’s essential for cleaner water, healthier fish, and a more stable system overall.

Optimize organic waste removal in RAS fish farming technology

- Organic waste builds up fast in recirculating systems—skimmers help nip that in the bud.

- Removing excess muck keeps water crystal clear and reduces stress on fish.

- A well-tuned skimmer setup enhances biofilter efficiency by minimizing solids before they even get there.

The right tech combo ensures that RAS operations run smoother with less downtime and fewer disease outbreaks caused by poor water conditions.

Enhance dissolved solids separation through foam fractionation technology use

• Foam fractionation isn’t just cool science—it’s a game-changer for separating out invisible gunk like proteins and lipids. • When dissolved organics float to the surface as foam, they’re skimmed off before they mess with filtration stages downstream.

This method of dissolved solids separation works best when paired with a fine-tuned protein-skimming device that can handle variable loads without choking up or losing flow rate.

Short-tail variations of the term “protein skimmer” are crucial here—think “foam extractor” or simply “skimmer tech”—since these tools specialize in capturing sticky compounds that would otherwise stay suspended in your tank.

Maintain pH stability and Redox potential improvement in recirculating aquaculture systems

A solid skimming setup doesn’t just clean—it stabilizes your whole aquatic environment:

- Keeps pH stability from swinging wildly during feeding cycles

- Improves Redox potential, boosting oxygen transfer and microbial balance

- Cuts down on CO₂ buildup, which often drives acidity spikes

In short bursts or over long-term cycles, this kind of balance means happier fish, less chemical intervention, and fewer headaches trying to correct preventable issues inside your recirculating aquaculture system.

Even if you’ve got other filtration gear running full tilt, integrating a foam extractor still adds an extra layer of polish—especially when you’re scaling operations or dealing with finicky species like trout or shrimp.

Protein Skimmer Vs. Mechanical Filter

It’s time to clear the waters—literally. Let’s break down how these two filtration champs keep your tank fresh.

Protein Skimmer

A foam fractionation unit, often called a skimmer, is more than just bubbles in a tube—it’s your tank’s silent cleaner. Here’s how it kicks organic waste to the curb:

Grouped Features & Benefits:

- Air Bubbles & Waste Capture: Tiny bubbles rise through a column, pulling dissolved gunk like organic waste and proteins along with them.

- Collection Cup Design: All that nasty buildup ends up in a removable collection cup, keeping it out of your water entirely.

- Venturi Injector Efficiency: With a solid venturi injector, air gets pulled into the chamber efficiently without needing extra pumps.

- Water Quality Boost: By removing invisible pollutants before they break down, it keeps overall water quality stable and fish-friendly.

According to Reef Builders’ 2024 Aquatic Systems Report, “foam-based filtration systems reduce nitrate buildup by over 35% compared to traditional mechanical-only setups.”

Mechanical Filter

While skimmers go after dissolved stuff, this one’s all about catching what you can see—and smell if left too long.

Grouped Key Components & Functions:

- Filter Floss & Sponges:

- These trap floating debris like uneaten food and plant bits using layers of fine mesh or porous materials.

- The density and shape of the media control how much gets caught—pore size matters here.

- Sediment Management:

- Larger particles settle out quickly in this system, helping maintain visible clarity.

- Great at reducing cloudiness caused by stirred-up substrate or messy eaters.

- Clarity Over Time:

- Regular cleaning ensures continued efficiency; clogged filters can become nitrate traps themselves.

- When paired with a skimmer, this combo is unbeatable—one tackles solids, the other hits dissolved stuff.

You’ll often hear aquarists say mechanical filters are your first line of defense—they’re not wrong. But don’t expect miracles on their own; they shine brightest when part of a full setup that includes foam-based filtration too.

Shrimp Farming: Skimmers Improve Water Quality

Skimmers are changing the game for shrimp farms—cleaner water, healthier shrimp, and fewer headaches.

Controlling ammonia and nitrate levels in marine shrimp farming application

• Excess ammonia can wipe out a shrimp tank fast—skimmers help prevent that. • Elevated nitrate leads to stress and disease susceptibility in marine shrimp. • A well-tuned system keeps the entire nitrogen cycle in check without chemical overuse.

By stripping organic waste before it decomposes, micro-bubble filtration tech reduces nitrogen spikes early on. That’s why smart farms are pairing their systems with YUTANK’s airflow-balanced skimming units.

Enhancing dissolved organic carbon reduction through counter-current flow configuration

- Organic matter builds up from feed waste and shrimp excretion.

- Counter-current setups create longer contact times between air bubbles and water columns.

- This improves removal of sticky compounds like dissolved organic carbon, which otherwise degrade water quality.

A reverse-direction bubble path traps more gunk—especially when paired with high-efficiency foam towers that use vertical space better than traditional skimmer bodies.

Improving water clarity in integrated aquaculture environments with foam fractionation

◉ Clear water isn’t just pretty—it’s essential for oxygen exchange and disease visibility. ◉ Foam towers using fractionation remove suspended particles that cloud vision inside tanks or ponds. ◉ In integrated systems, where multiple species share space, clarity helps keep everything stable.

A good skimmer setup pulls out proteins before they rot, keeping your aquaculture system cleaner without needing constant manual intervention.

Ensuring consistent foam production with airflow rate optimization processes

Airflow matters—a lot more than you’d think when it comes to foam generation.

Too little air? You don’t get enough contact time for efficient protein binding. Too much? Foam collapses before separation happens properly. By tuning airflow based on temperature shifts and stocking density, farmers ensure steady performance from their foam towers day and night—even during feeding peaks or heatwaves.

Comparative Efficiency of Skimmer Configurations on DOC Reduction (%)

| Configuration Type | Airflow Rate (L/min) | DOC Reduction (%) | Power Consumption (W) |

|---|---|---|---|

| Co-current Flow | 20 | 38 | 120 |

| Counter-current Vertical | 25 | 61 | 135 |

| Horizontal Chamber Design | 18 | 42 | 110 |

| Hybrid Spiral Intake | 22 | 58 | 130 |

Counter-current designs outperform others across the board—more DOC pulled per watt consumed makes them ideal for long-term ops.

Boosting protein skimmer efficiency by balancing biological load fluctuations

Short bursts of heavy feeding mess with skimming efficiency if you’re not ready for them.

– Sudden increases in biological load spike organics fast; this requires real-time adjustment capabilities. – Protein-removal units must adapt quickly or risk buildup of harmful compounds. – Systems using auto-adjustable airflow valves respond faster than manual controls, keeping things smooth even during peak metabolic periods from growing stock.

Balancing these loads means less downtime—and happier shrimp overall.

Key variables influencing optimal protein skimming performance in tropical aquaculture climates

Short segment breakdown:

• Temperature swings alter bubble behavior inside skimmers dramatically. • Salinity affects how efficiently proteins stick during foam formation. • Stocking density determines how often you’ll need maintenance cycles. • Higher humidity levels reduce evaporation rates but may increase microbial activity near surface tension zones. • All these impact how well your unit maintains clean conditions under pressure in tropical zones where environmental control is harder than usual.

Smart farmers track these variables weekly—not monthly—to fine-tune their systems proactively instead of reactively fixing problems later on.

Practical tips for integrating protein separation into small-scale farming operations

Step-by-step:

Step One – Choose a compact model suitable for your tank size; overkill wastes energy fast. Step Two – Calibrate the airflow valve based on your average daily feed input—not just max capacity numbers listed online. Step Three – Clean collection cups regularly; even small clogs ruin output quality over time. Step Four – Monitor pH closely after startup; some models shift buffer balances temporarily due to gas exchange changes introduced by microbubbles.

Even if you’re running a backyard pond setup, proper integration makes all the difference between hobby success and a stinky disaster zone no neighbor wants near them!

FAQs about Protein Skimmer

How does a protein skimmer improve water quality in a recirculating aquaculture system (RAS)? A well-tuned protein skimmer quietly transforms the chaos of organic waste into clarity. As uneaten feed and fish waste begin to dissolve, they release compounds that can tip the balance of your tank’s chemistry. The skimmer intercepts these before they become harmful—pulling organics out as foam, stabilizing pH, and giving your biofilter room to breathe.

Is combining a mechanical filter with a protein skimmer more effective than using one alone? Absolutely. Each plays its part:

- Mechanical filters trap visible particles like leftover food or sludge.

- Protein skimmers target what you can’t see—dissolved organics floating invisibly in the water column.

Together, they create cleaner conditions faster than either could on their own.

Why is airflow rate so important for consistent performance? Airflow isn’t just about bubbles—it’s about timing and precision:

- Too little air? Waste slips through untouched during feeding peaks.

- Too much? You get unstable foam and wasted energy.

Dialing it in means steady removal without overworking your system—or your electricity bill.

Can using a protein skimmer help lower total suspended solids (TSS) levels in RAS setups? Yes—and not by accident. As fine particulates swirl around tanks unnoticed by larger filters, the counter-current flow inside the skimmer traps them within rising foam columns powered by Venturi-driven microbubbles. It’s like watching invisible dust finally find gravity.

What design features matter most when choosing an efficient protein skimmer for aquaculture use?Look beyond size or price tags:

- A conical body helps guide foam upward without collapse.

- Adjustable water level control lets you respond quickly to changes from feeding or stocking.

- An easy-to-clean collection cup keeps maintenance light while ensuring peak operation daily.

These aren’t bells and whistles—they’re essentials when uptime equals survival rates.